SPECIALITY FIBRES AG

MATERIALS

WHAT IS »CASHMERE«?

»Cashmere« is the fine bottom layer hair of a special goat race, named »capra hircus laninger«. The living space is Central Asia, the Himalaya and Pamir regions, as well as the Inner- and Outer Mongolia. The finest qualities can be found at the Inner Mongolia and have a fineness of 14,5 to 15,5 micron (1 Micron = 1 thousandth Millimeter) plus very silky, soft qualities from the Outer Mongolia, with 16 – 16,5 micron. In comparison to cashmere fine merino wool has approx. 19 micron and normal sheep wool approx. 22 micron. The very fine under-or fluff hair, also called »duvet« is developed by the goats due to the harsh environment of these regions, with summer temperatures of 23-35 C and up to – 40 C in winter time and undernourishment caused by meager feed offers

HISTORICAL RETROSPECT

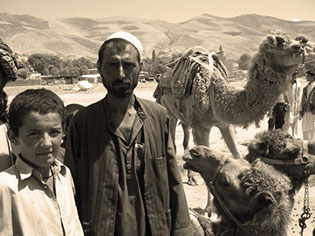

Originated in the east of Turkey, the Cashmere goat did widespread up to Central Asia. Still today it was and is the main source of income to the nomadic people (milk, meat, leather, skin). The migration movements of the Turks brought the technic of weaving scarfs up to Srinagar, today proprietary to India’s province Cashmere. In the beginning applied to sheep wool, but then encouraged through the ruling Mogul cashmere was processed, too. The raw material did not exist in Cashmere, but came from the tableland of Tibet and was bartered against staple food. Thousands of prosper, little weaving mills did arise and the goods were exported to the Mideast. Knowledge of these legendary scarfs, which could fit through a finger ring, was spread by the English and Portuguesa sailors to Europe. But it was only after the French royal court, especially empress Eugenie, the wife of Napoleon III, that made these cashmere scarfs a »must have« fashion item all over Europe. Today the Italians are market leader of high level textiles and have developped excellent expertise, especially in knitwear.

GAINING OF »CASHMERE«

The fine fluff hair of the cashmere goats gets loose after the winter and in spring time. As soon as the temperatures rise, the fur is getting combed out and the fibres are sorted according to colour and fineness.

In the next step the upper layer and bottom layer will be separated. This is done with machine processes, close to combing. Besides the coarse hair also vegetable matters and dandruff gets removed. The result is called »dehaired cashmere«. The outcome of one animal is approximately 100 – 250 g of raw cashmere with the yield of 50 – 120 g dehaired cashmere. Material of 3 – 4 goats is needed for one knitted sweater.

A large variety of qualities do exist, depending on the count of coarse hair left, the length and fineness of fibre. This is essential for the quality and the further treatment und therefore the final result.

TEXTILE MANUFACTURING

Dehaired cashmere is the basic product of the yarn production. The finest and most valuable yarns do have a fineness of NM 28/2 that means 1 kg of this yarn is 28 km long. Additionally it is twisted and therefore strong and valuable. A common way to save material is knitting the sweaters in one piece, but the look is correspondingly. A lot of products from Asia are manufactured this way. Complex, but very high quality is the knitting of adjusted pieces. It requires electronic, programmable knitting machines. The pieces are made ready to fit (front-, back,-sleeves) and have to been sewn together. This might be more expensive but on the other hand much better fitting and more elegant.

THE CHARACTERISTICS OF »CASHMERE«

Cashmere is the most luxurious noble fibre, which is used in commercial quantities. Due to its limited production and history this fibre has an almost magical attractive effect, as well as a first class image. The fascination for this fibre builds on its softness, affectionate, fineness and flexibility, which can hardly be reached by any other spinning fibre. It is supplemented by a fine, silky shine and lightness that does add up to a very comfortable carrying property. And last but not least this fibre has very good moisture absorption qualities (up to 30%) as well as heat retention for highest comfort.

A disadvantage is the responsiveness of this material to mechanical demands (caused by the fineness of this fibre). This may cause pilling quite easily. After wearing the sweater should rest for one day. Hand wash with less than 30 C and wool detergent should be used, rinsed several times with cold water, but not wringed or squeezed strongly and on no account centrifugation. It should be dried flat lying on a towel.

YAK

Yaks are mainly domiciled in Central-Asia. They have a multilayer and very compact coat. There are two main qualities, the coarse top-layer and the finer bottom-layer. Per year about 3kg of coarse wool and 0,5 kg of fine wool can be gained. The fine wool suits very well for the production of spinning yarn; the hair is harvested by combing or shearing.

NATURAL SILK

Silk is the sole natural continuous fiber and gained from the cocoons of the silkworm. Already 5000 years ago the production of silk was known in China and this knowledge was kept a secret for almost 3000 years. Around 300 b. Ch. the abutting nations like Japan, India, Persia and the Orient became acquainted to silk and manufacturing. In the 6th century it reached Europe through the today still known silk route. Not before the 1150 a serious production of silk was started in in Europe by the Italians. Silk stands out due to its soft and elegant shine, which no other textile yarn reaches. The fineness of 7 – 20 micron and a specific weight of 1,37 is topped by very fine woolen yarns, only.

Natural silk – is very smooth and crease-resistant. It protects from coldness and heat and has a natural high elasticity and stability.

Mulberry silk – is silk harvested from the purl seam of silk spinners, mostly eating leaves of the mulberry trees. They are kept as farm animals and do spin a very fine and regular thread. By reeling off the middle section of the cocoons an up to one kilometer long thread can be gained, the so-called continuous fiber. The bast can be removed quiet easily, generating a very fine fiber with dimensions of 7 – 20 my, almost pure white and smooth.

Tussah Silk – The oak egger, a night butterfly is not raised in farms and feeds mostly on the leaves of oaks. He produces a cocoon whose shell consists of loose threads which can be reeled off comparatively easy. The gained silk is less regular, thicker, and duller. It has a harsher hand feel compared to mulberry silk. This silk is mostly used in its natural colour, the cloth has the characteristic irregularity, a wanted effect.

CAMEL HAIR

Camels live mostly in Asia and Africa. The coat is split into two layers, the guard hair, rather plain and coarse and the bottom hair, being crimpy and soft. The hair is neither clipped nor brushed out, but falls out naturally in bunches at springtime. In the textile branch mainly the valuable bottom hair is processed for spinning yarns. Due to its softness, rarity and fineness the bottom hair is often blended with pure new wool. Pups due have an almost white and fine hair, which is especially demanded. It is trade under the name »Baby-Alashan«. Camel Hair has very good isolation characteristic. Having a low weight it is at the same time fluffy and airy. It is suitable to manufacture coats and covers.